Concentrating Solar Power (CSP) is a technology that involves using a large-scale array of parabolic reflectors or mirrors to collect solar thermal energy. This heat energy is used to generate steam to produce electrical power with traditional turbines as are used in fossil fuel and nuclear plants today.

Currently, CSP technology exists in four common forms; Solar Power Tower, Parabolic Trough, Dish Stirling, and Concentrating Linear Fresnel Reflectors.

Solar Power Tower and Parabolic Trough are the two main approaches used for large-scale CSP systems.

CSP Ultra Lite Solar has developed a trough technology using thin film material and air pressure enhanced structures to significantly reduce the complexity and cost of solar concentrators used in CSP plants. This could enable much higher capacity factors to support 24 hour power production economically.

Why produce power with Concentrating Solar Power?

Photo Voltaic (PV) technology produces electricity with semiconductor material. These have come down in cost over the last several years to the point of being less expensive than traditional CSP. PV’s have a capacity factor of about 17%. That means they typically only put out 17% of its rated capacity per day. They do not produce power at night.

CSP without storage has a capacity factor of about 20%. Energy storage is needed to increase the capacity factor for night time power production. Storing the electrons produced by PV panels is expensive, to the extent that it is rarely implemented. You would need batteries or flywheels to store electricity. CSP on the other hand produces heat which is far less expensive to store.

Traditional CSP

A typical CSP plant may have enough storage to add 4 to 6 hours of extra production at night. These plants typically don’t have overnight storage since the solar field has to be made larger to accommodate not only daylight production but to produce enough additional energy to store for night time production. This becomes prohibitively expensive.

Traditional solar concentrators use a metal super-structure, usually made of aluminum or steel and glass mirrors. The super-structure is complicated as it has to support the mirrors rigidly to conform to the parabolic shape required to focus sunlight. The glass mirrors are also heavy, requiring a strong structure to hold the weight.

Ultra Lite 1 Innovation

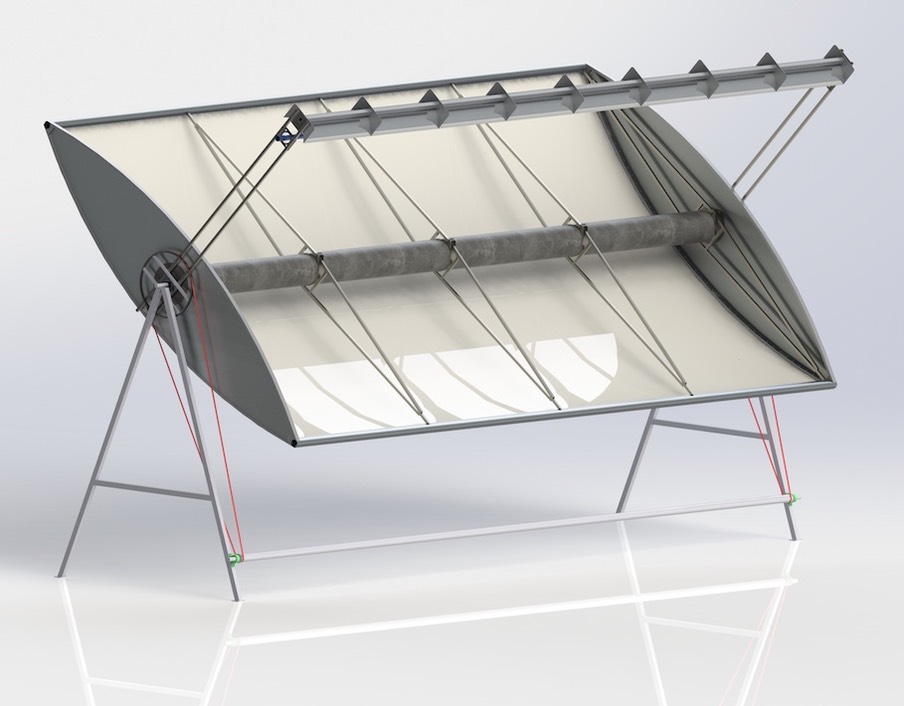

The CSP Ultra Lite Solar innovation greatly simplifies solar concentrator design by using a simplified light weight structure made possible with the use of differential air pressure as a structural component. Instead of using rigid glass mirrors, flexible mirrors are used in the form of a loose film material. This material can be almost any composition such as a polymer, thin glass, or metal and can be as thin as a few thousandths of an inch thick. The contour of the reflective film is shaped with air pressure. Several embodiments of this are possible. The following illustration shows how differential air pressure shapes a thin film over a framework. The thin walled, light weight framework is further strengthened with air pressure within its structural components. Again air pressure is used as a structural component. This results in a dramatic reduction in complexity, materials and costs. It now becomes possible to build much larger solar fields to store enough energy for overnight power generation and to do so economically. Other benefits of CSP Ultra Lite include:

- Laminar flow design, minimizing wind loading dramatically compared to open flective designs.

- Protected reflection layer is internal to the structure in a controlled dry air atmosphere, prolonging reflective surface lifetime.

- Low cost linear receivers for lower temperature applications.

The Big Advantage

The big advantage for CSP plants is the ability to be base-load plants economically. This means the reliance on a traditional power plant for backup is no longer required and the cost of duplication of infrastructure is eliminated. CSP plants designed with overnight storage can produce power nearly 100% of the time. On a cloudy day the overnight storage can become depleted. It is possible to build multi-day storage capacity, but this adds to the plant cost. Instead the power plant can use traditional fossil fuels as a backup. The same turbine would work on either fossil fuel or solar energy.

The technology can also be retrofitted to some existing power plants with the addition of a solar field. This can become an economical solution to an existing power plant since this infrastructure is already in place.

Real Plant Economics

Learn more about the Levelized Cost of Electricity (LCOE).

How this technology can benefit you

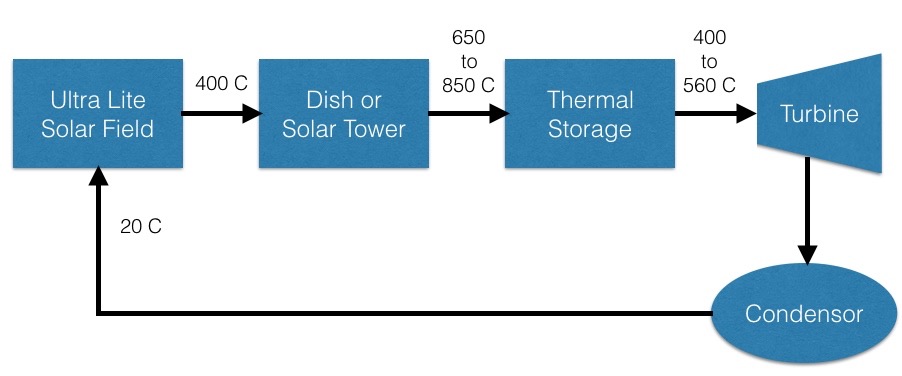

This technology can be used in place of traditional trough concentrators and can also be used in conjunction with higher temperature dish and tower technologies to lower costs.

A great deal of energy is required to overcome the latent heat of vaporization.

If we assume a Solar Tower generates 650 C and Ultra Lite provides 400 C preheat to the Solar Tower, then:

Amount ot heat required to rise temperature:

Q = cp m dT

where

Q = amount of heat (kJ)

cp = specific heat (kJ/kg.K)

m = mass (kg)

dT = temperature difference between hot and cold side (K)

To heat water from 20 C to 400C:

Q = (4.19 kJ/kg.K) (1.0 kg) ((100 oC) - (20 oC))

= 335 (kJ)

Latent Heat of Vaporization (kJ kg-1)

= 2257 (kJ)

Q = (4.19 kJ/kg.K) (1.0 kg) ((400 oC) - (100 oC))

= 1257 (kJ)

Total = 3849 kJ

To heat water from 400C to 650 C:

Q = (4.19 kJ/kg.K) (1.0 kg) ((650 oC) - (400 oC))

= 1047 (kJ)

In a combined technology plant, the Ultra Lite trough concentrators can be used as a preheat to higher temperature dish and tower systems. The Ultra Lite troughs can boost the temperature from 20C to 100C, go through the latent heat of vaporization and continue to heat to 400C. This is where most of the energy is required 3849 (kJ). The temperature can then be boosted by dish or tower systems to higher operating temperatures such as 650 to over 800C. This temperature boost requires far less energy. Only 1047 (kJ) to heat from 400 to 650 C. Most of the plant can consist of low cost Ultra Lite Concentrator and a much smaller number of dishes or heliostats.

The advantage of the temperature boost allows much higher efficiency turbines to be used, potentially boosting plant efficiency by up to 100%. This means the solar field could be reduced by 50% overall, saving huge costs while providing the same power. Combining the technology can potentially reduce the LCOE more than using the technologies singularly.

Ultra Lite 3 Innovation

Ultra Lite 3 uses mirrored film adheared to an aluminum sheet that is held in a parabolic shape with a super-structure. A low-cost, low-temperature (up to 200 C) linear receiver replaces expensive “evacuated tube linear receivers” for process heating and Organic Rankin Cycle (ORC) power generation applications. ORC is ideal for industrial CSP applications.

Point Focus Dish

Concentrators

CSP Ultra Lite Solar had previously developed a point focus technology. This technology is more expensive, and may not be directly competitive in itself, which is why the Ultra Lite technology was developed. However, when combining this technology with the Ultra Lite technology as explained above, overall costs can be reduced.

CSP Ultra Lite Solar can add its point focus technology to its Ultra Lite solar fields to boost temperatures for higher temperature turbines. This is most useful when retrofiting existing coal fired power plants that use higher temperature turbines. A solar field could typically be comprised of 90% Low-Cost Ultra Lite Trough concentrators which preheat to about 400C and about 10% point focus consentrators that can boost temperatures up to 850C.

This higher temperature allows enough thermal differential in the thermal storage system to operate turbines in the 400 to 450C range.

According to Wikipedia the solar to electric efficiency of a trough plant is about 15%. We assumed 25% in a combined technology plant, but just to go with trough, we will use the 15% number. Therefore: 1 array would have an estimated output of 3 kW.

1MW plant would require 333 arrays.

10 MW -> 3,333 Arrays.

100 MW -> 33,333 Arrays.

500MW ->166,667 arrays.

Ref: https://en.wikipedia.org/wiki/Parabolic_trough